SERVICE

A full range of manufacturing services to quickly verify your product designs.

CATEGORIES

A variety of services to meet the needs of customers in different industries and fields.

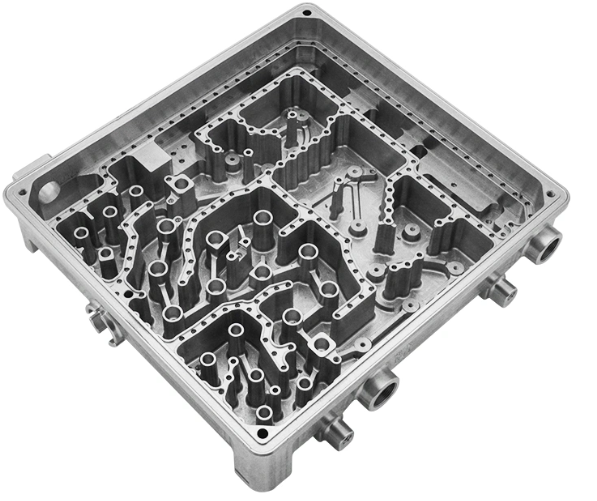

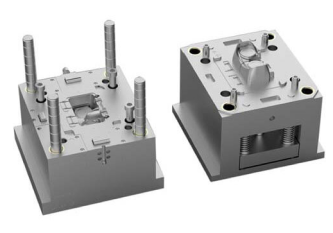

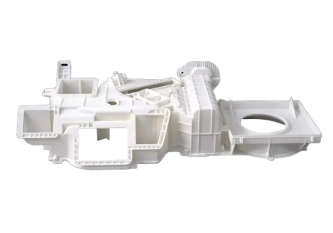

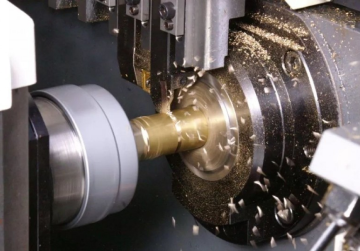

CNC Machining

CNC Machining is a manufacturing process in which pre-programmed computer software dictates the movement of machinery which is able to produce tight tolerances, complex geometries and product-like prototypes as well as single piece parts in short to medium production runs.

PRODUCTS

A full range of manufacturing services to quickly verify your product designs.

INDUSTRY

Covers multiple areas to solve various technical problems and problems for customers.

Car

Aerospace

Consumer Electronics

Medical Equipment

Household appliances

Robot

NEWS

Pay attention to the latest developments in Huaguan and grasp the latest information in the industry.

Understanding the Advantages of Passivated Galvanized Sheet Metal Parts in Manufacturing Processes

2024-12-08

Understanding Electropolished Sheet Metal Auto Parts: Benefits and Applications

2024-12-03

Advantages of Incorporating Electropolished Sheet Metal Auto Parts in Industrial Machinery

2024-11-28