Service Center

Services

Contact Us

Huaguan Prototype Co.,Ltd.

Phone: +86 0755 2322 2132

Email: info@hg-prototype.com

Address: 1st Floor, Building 18, Second Industrial Park, Heshuikou Community, Matian Street, Guangming District, Shenzhen ,China 518106

|

|

|

|

|

CNC Machining is a manufacturing process in which pre-programmed computer software dictates the movement of machinery which is able to produce tight tolerances, complex geometries and product-like prototypes as well as single piece parts in short to medium production runs.

Prototyping is the process of making models, models, and displays, and is the first step in testing the feasibility of a product. The prototype was the first sample produced. Designers usually use this method to obtain prototypes to observe the advantages and disadvantages of his new products, so as to avoid wasting too much time, money and manpower in the process of rapid prototyping. This helps designers visualize and iterate products before they go into mass production.

Surface finishes not only make prototypes and final products look aesthetically presentable and unique, but also crucial in ensuring that they can perform as intended to and last longer as finishes provide protection from outside elements, corrosion, wear and rust.

Lathe processing is part of the mechanical processing, with two main forms of processing:one is to fix the turning tool, processing the unformed workpiece in rotation; The other is to fix the workpiece, through the high-speed rotation of the workpiece, the lateral and longitudinal movement of the tool (tool rest) for precision machining. Lathes are mainly used for machining shafts, discs, sleeves and other workpieces with rotating surfaces.

Sheet metal processing is a manufacturing process in which a piece of metal plate is formed into a desired part through material removal and/or material deformation. The metal plate can be cut, bent, stamped and drawn into any shape. Sheet metal can be formed into small parts such as gaskets or brackets, or medium-sized housings for household appliances such as computer cases, up to large cases for cars.

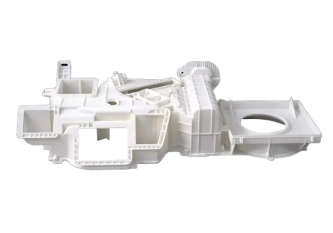

Vacuum casting is an economical processing method that alternate to small batch injection molding of plastic parts . It is areat method to make rigid or flexible parts, and is ideal for high quality prototypes, function testing, concept proofing and display demos. The process produces parts with colors, textures, mechanical properties and surface finishes comparable to those made with injection molding.

3D Printing is a process of making three dimensional solid objects by laying down successive layers of materials until the object is created.3D printing creates prototypes quickly, allowing you to touch, see, and test your design in physical form,which can be used to create complex geometries that could not be realised using traditional manufacturing processes. 3D printed prototypes allow moving parts, colorization, and much more.

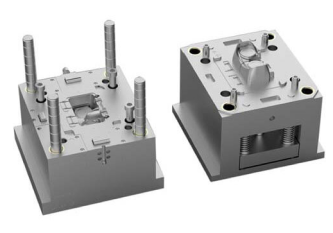

The injection molding process refers to the process of making melted raw materials produced by compressing, injection, cooling, and departure.

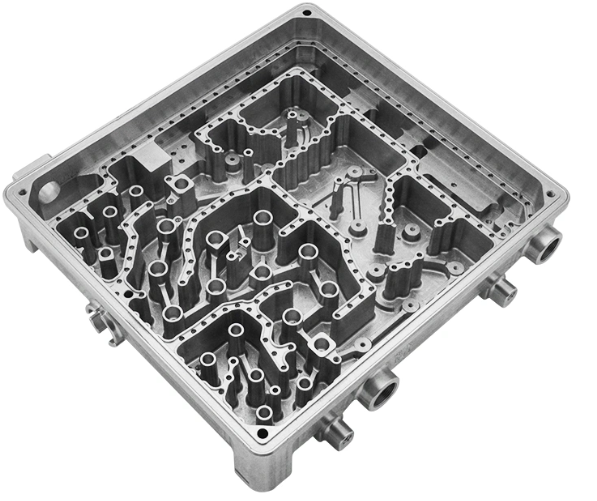

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mould cavity. The mould cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mould during the process.. Commonly used die casting materials for machine parts include aluminum alloy, zinc alloy and magnesium alloy.Metal parts provide advantages such as heat-resistance, pressure-resistance, and corrosion-resistance for uses in many applications,including Medical,Manufacturing parts ,Automotive, Aerospace and more.